Steel Grating

Steel Grating can meet almost any load bearing or weight requirement and is the most durable grating for rugged applications. Bar grating is a top choice for strength, safety, and long-term cost.

Products description

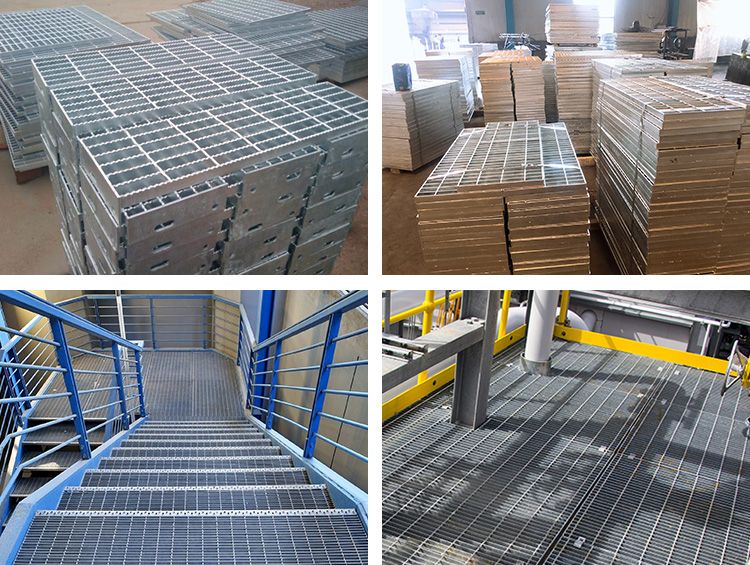

Steel Grating

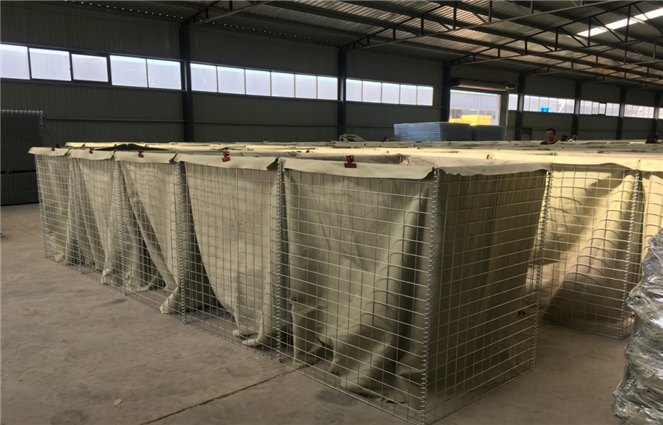

Steel grating is a type of metal structure that consists of individual metal bars that are joined together to form a lattice or grid pattern. The bars are usually made of steel and are spaced apart in a regular pattern, allowing for light and air to pass through. Steel grating is used for a wide range of applications, including flooring, decking, stair treads, trench covers, and fencing.

There are several types of steel grating, including welded steel grating, press-locked grating, swaged grating, and close mesh grating. The type of grating that is best suited for a particular application depends on various factors, such as the load requirements, the environment, and the desired appearance.

Steel grating is highly durable and can withstand heavy loads, making it ideal for use in industrial, commercial, and construction applications. It is also resistant to corrosion, fire, and extreme temperatures, which makes it suitable for use in harsh environments. Additionally, steel grating is relatively low-maintenance and can be easily cleaned and painted to maintain its appearance.

Choosing the best materials for your grating products

We use high quality metal grating made from aluminium and steel in a wide range of styles and applications.

Carbon steel: Carbon steel offers an economical, high-strength grating suitable for most industrial and commercial applications.

Aluminium: Lightweight, corrosion resistant and non-sparking alloys make aluminium ideal for chemical, petroleum, hydro and food processing plants, water and waste treatment facilities; munitions plants and other volatile areas; on ships; ETC.

Stainless Steel: Stainless steel grating is ideally suited for use in corrosive environments where corrosion resistance and minimal carbide precipitation are important considerations. Particularly suitable for use in chemical, food and hydrogenation applications.

There are several advantages to using steel grating:

Durability: Steel grating is highly durable and can withstand heavy loads, making it ideal for use in industrial, commercial, and construction applications.

Low Maintenance: Steel grating is relatively low-maintenance and can be easily cleaned and painted to maintain its appearance.

Corrosion Resistance: Steel grating is resistant to corrosion, making it ideal for use in harsh environments where it is exposed to moisture and other corrosive elements.

Fire Resistance: Steel grating is resistant to fire, making it a good choice for applications where fire safety is a concern.

Versatility: Steel grating is versatile and can be used for a wide range of applications, including flooring, decking, stair treads, trench covers, and fencing.

Cost-Effective: Steel grating is a cost-effective material compared to other materials such as concrete and wood.

Lightweight: Steel grating is lightweight, making it easy to handle and install.

Good Drainage: The open design of steel grating allows for good drainage, which is important for applications where fluid or waste needs to be removed quickly and efficiently.

Ease of Installation: Steel grating can be easily installed and does not require specialized equipment or techniques.

What's more, metal gratings often offer the best solution for situations where a high strength-to-weight ratio is required.

We are the leading experts in customised gratings

Xinghong stocks only the highest quality steel products. In addition to our large stock of bar grating products, we will customise any of our products for your specific application. Our facilities include an in-house fabrication shop that is equipped with the necessary tools and technical expertise to manufacture a unique product to meet your requirements.

We will use your existing drawings or blueprints to produce print proofs to help you select the perfect aluminium or steel grille product for almost any application. Our team will work closely with you throughout your bespoke project. Our focus is on bringing your design ideas to life in order to provide bespoke bar grating solutions that solve problems in a timely and cost effective manner.

Contact us today to find out how our specialist bar grating manufacturers can help your job run smoothly.

Specification

| Series | Pitch of Bearing bar | Cross-bar Pitch | Specification of bearing bar load(width×thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | |||

| 1 | 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | ||

| 2 | 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | ||

| 3 | 60 | 50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 | |

| Series | Pitch of Bearing bar | Cross-bar Pitch | Specification of bearing bar load(width×thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | |||

| 1 | 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | ||

| 2 | 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | ||

| 3 | 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |

When to use metal bar gratings

Flooring

Stairs, stair treads and cross platforms

Sewage drain covers, manhole covers, forklift traffic and loading ramps

Shelving and shelving

Walkways

Fire escape ladders, light guards and loading ramps

Mezzanines and platforms

Filling panels

Container interiors and catalyst support grids

Bridge pavements and bridge decks

Architectural uses such as building facades or partition walls

Security screens in residential and commercial buildings

Grids have a wide range of uses, from floors and stairs to bridges and sewer covers. It is a sensible choice for floors and stairs in work areas where slips and falls are a major problem (such as industrial plants, waste water treatment facilities or manufacturing operations). The open design makes the strip grating the perfect choice for areas where light needs to pass through. It is also suitable for projects that require quick and easy fabrication and installation.