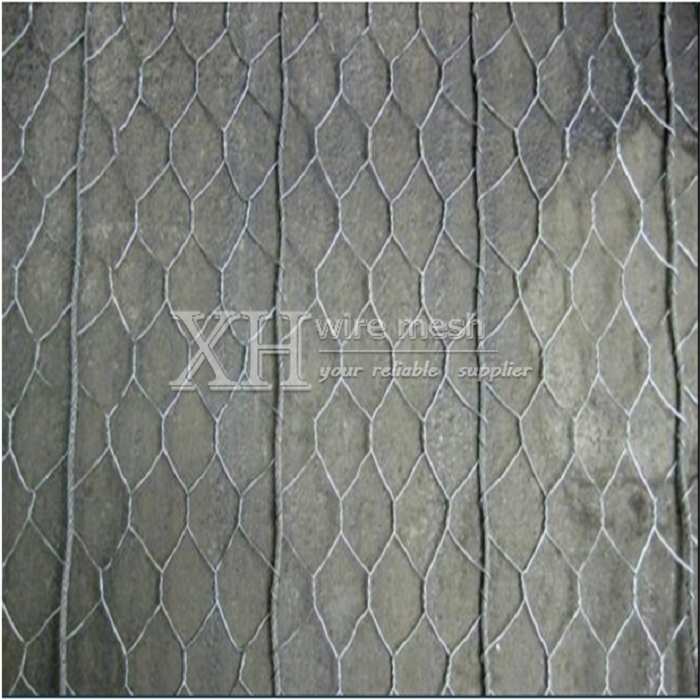

Rockfall netting

The high tensile rockfall netting system is installed in the same general way as conventional double twist mesh. It is easy to handle and will not require extensive modification of existing method statements and installation techniques. The inclusion of the steel ropes greatly enhances the transfer of loads from the mesh into the anchorage system thereby increasing the safety, capacity and durability of the mesh as a complete system.

Products description

Rockfall netting is placed on hazardous slopes and vertical rock faces to passively or actively stop the threat of falling rocks and rocks. They are open mesh structures that allow free drainage and vegetation establishment. They can cover the entire threatened rock surface or only a portion of it.

The high tensile rockfall netting system is installed in the same general way as conventional double twist mesh. It is easy to handle and will not require extensive modification of existing method statements and installation techniques. The inclusion of the steel ropes greatly enhances the transfer of loads from the mesh into the anchorage system thereby increasing the safety, capacity and durability of the mesh as a complete system.

Where is rockfall netting used?

Rockfall netting is an efficient mesh that combines ease of use and flexibility with unmatched cost-effectiveness. Typically used as a "source control" measure, Xinghong Metal Wire Mesh's rockfall netting has been used around the world and has proven to provide strong, durable and cost-effective rockfall protection. On moderately steep slopes or slopes where some vegetation may be growing, the mesh should be placed as close to the slope as possible. On very steep and/or near-vertical slopes, the net must be anchored at the top of the cliff while remaining unanchored at the bottom, thus allowing rocks and debris to fall into a collection trench at the toe of the slope.

Benefits

● Does not break apart if a break in the wire occurs, making it cost-effective and requiring low maintenance

● Flexibility to match existing slope and rock profiles

● Different levels of coating protection to maintain durability in a variety of environments

● No inhibition of vegetation regeneration

● No overlapping webs on lateral joints mean fast installation and minimal material waste

Specification

| Properties | ||||

| No | Properties | Standard/Code | Unit | Specification |

| MESH WIRE PROPERTIES | ||||

| 1 | Mesh Opening | EN 10223-3 | mm | 80 |

| 2 | Mesh Type | EN 10223-3 | cm x cm | 8x10 |

| 3 | Roll Width | Standard width | m | 2.7 |

| 4 | Roll Length | Specific Requirement | m | 25 |

| 5 | Spacing of longitudinal Wire Rope | - | cm | 32 (±2) |

| MESH WIRE PROPERTIES | ||||

| 1 | Wire Diameter | EN 10223-3 | mm | 2.7 (±0.05) |

| 2 | Tensile Strength of Wire | EN 10223-3 | N/mm2 | 350-550 |

| 3 | Elongation | EN 10223-3 | % | ≥10 |

| 4 | Zn 90%-Al 10% Coating | EN 10244 -2, class A | G/m2 | ≥245 |

| 5 | Zinc Coating Adhesion | EN 10244 | - | No flaking of the zinc coating |

| WIRE ROPE 8MM | ||||

| 1 | Construction of Wire Rope | EN 12358-4 | - | 6x7 -WSC |

| 2 | Diameter of Wire Rope | EN 12358-4 | mm | 8.0 |

| 3 | Rope Grade | EN 12358-4 | - | 1770N/mm2 |

| 4 | Breaking Load of Wire Rope | EN 12358-4 | kn | ≥41 |

| 5 | Mass of Zn 95%-Al 5% Coating | EN 10264-2, class A | - | ≥150 |

Buy wire mesh from a reliable manufacturer

Xinghong Metal Wire Mesh is a professional rockfall netting manufacturer and supplier, offering a wide range of screen products, contact us to get samples!